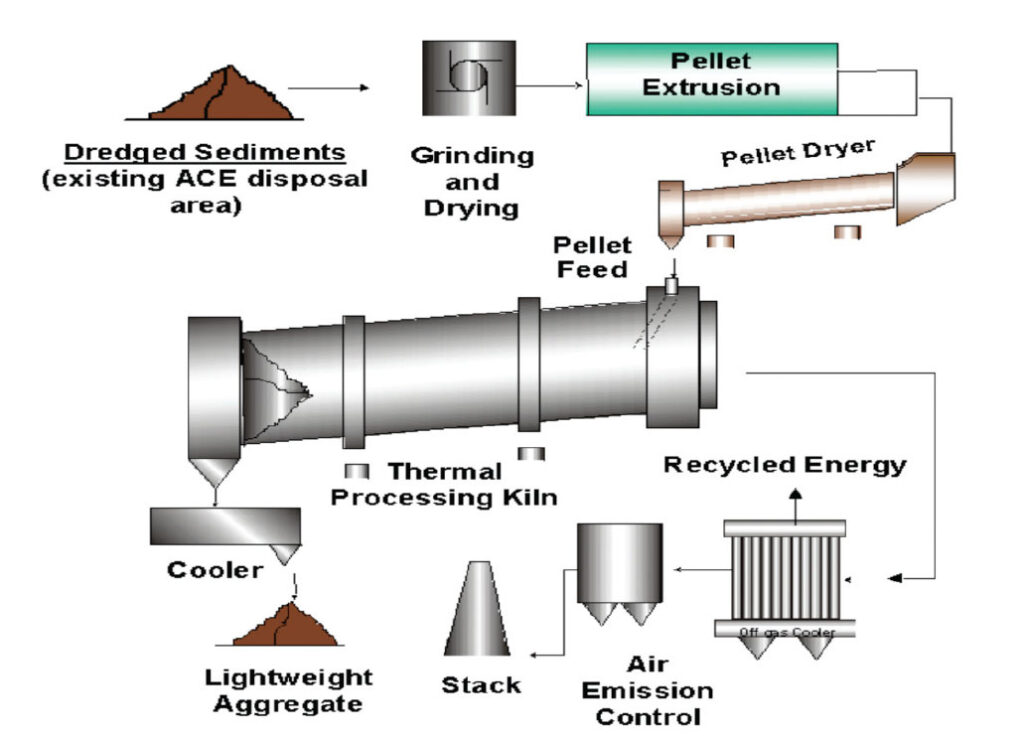

Our state-of-the-art process is able to effectively destroy organic compounds and bind metals within the aggregate matrix. The end product has been proven to be inert and pass all environmental tests. Key steps in the process include:

- Screening to remove unusable materials

- Grinding and extrusion to form pellets

- Pellets are fired in a rotary kiln operating at 2,000° F to make a high quality aggregate

- Aggregate is crushed and graded to meet customer requirements

Simplified HarborRock Process Flowsheet

The HarborRock process operates continuously and is able to process large volumes of sediment materials, with plant sizes ranging from 250,000 CY/year to over 2,000,000 CY/year. The plant size is determined by factors such as the quantity of raw materials available, the supply frequency of new material, and raw material storage capacity. HarborRock has been recognized by state and federal governmental agencies as a premier technology for the beneficial reuse of dredged materials.

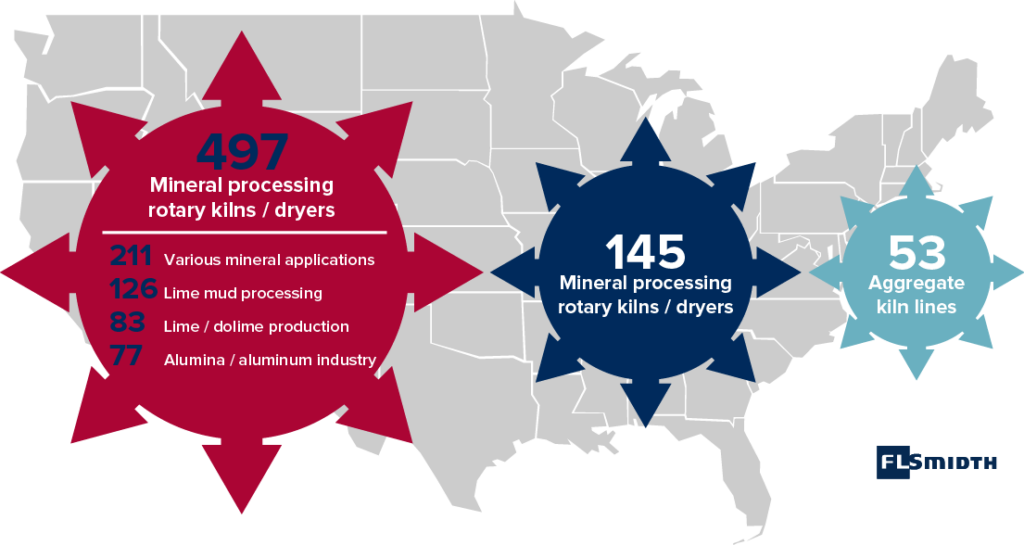

Pyroprocessing Equipment and Processes Used Globally

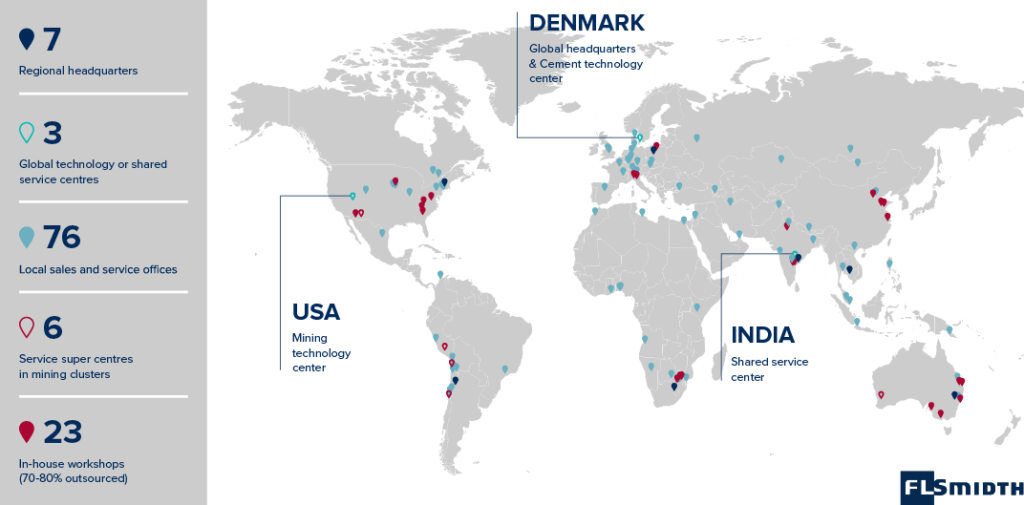

HarborRock’s equipment provider and process designer, FLSmidth, has mining and pyroprocessing equipment in use across thousands of facilities globally in the aggregates, cement, and mining industries.

USA Facilities Using Similar FLSmidth Equipment and Processes

FLSmidth has over 600 facilities throughout the USA alone using similar equipment and processes to HarborRock’s conversion and reuse facilities.